The Casual Furniture Company

The Casual Furniture Company (CFC) makes a variety of bookshelves for homes and businesses. The shelves come in various heights, widths, materials, and finishes. Effective requirements planning is essential for CFC’s performance, and it uses MRP for planning.

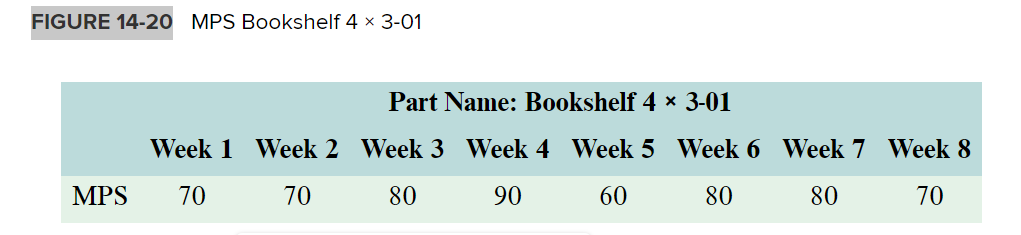

The MPS and MRP records are shown for one of CFC’s products, part number 4 × 3-01, a four-foot-high and three-foot-wide standard depth oak bookshelf. The BOM as a product structure diagram is shown in Figure 14-19.

FIGURE 14-19 Bookshelf 4 × 3-01 BOM

CFC uses one-week time buckets and a planning horizon of eight weeks. The MPS for the 4 × 3-01 Bookshelf is shown in Figure 14-20.

FIGURE 14-20 MPS Bookshelf 4 × 3-01

The Casual Furniture Company

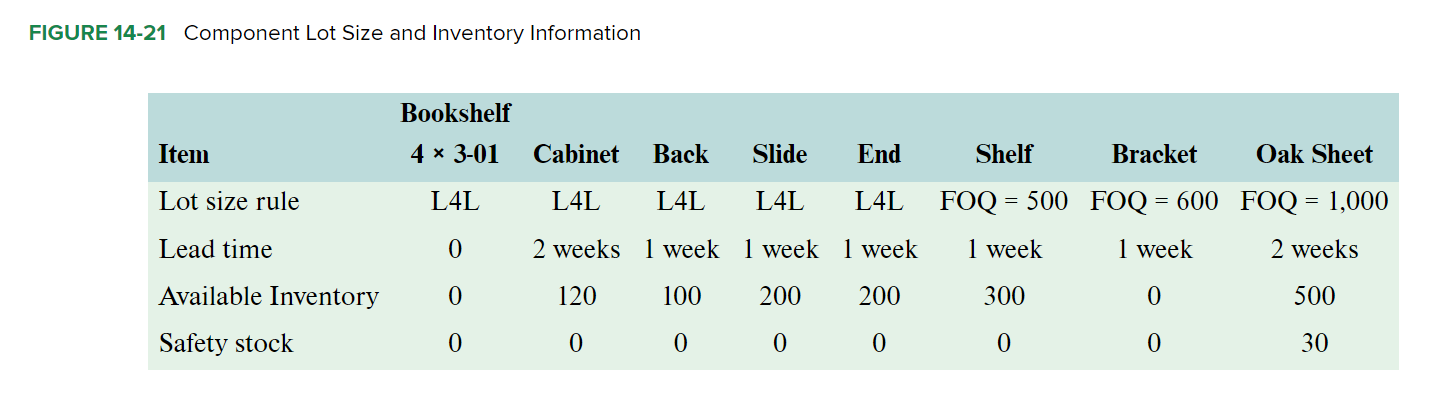

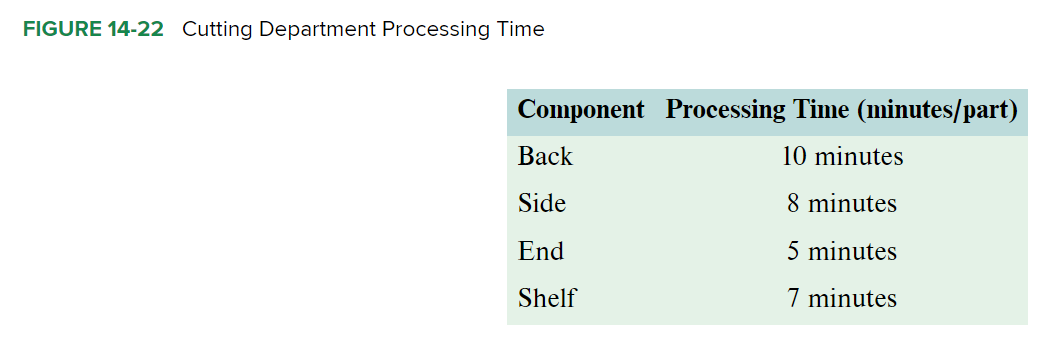

The cabinets are built in the cabinet assembly department and the shelves, backs, sides, and ends are made in the cutting department. The component lot size, lead time, available inventory and safety stock are shown in Figure 14-21. Two associates work in the cutting department, making the available capacity 80 hours per week, without overtime. The processing time for each component in the cutting department is shown in Figure 14-22. Also note that there is a scheduled receipt of 600 brackets in week 1 and a scheduled receipt of 1000 oak sheets in week 1. APA.

FIGURE 14-21 Component Lot Size and Inventory Information

FIGURE 14-22 Cutting Department Processing Time

The Casual Furniture Company

Questions

- Develop the MRP for all of the components.

- During week 1 of the plan, the bracket supplier notifies CFC that the order for 600 units will not arrive as planned. Instead, 300 will arrive this week and 300 will arrive next week, instead of all 600 arriving at the same time. Will this affect production and, if so, to what extent?

- Now that the plan has been developed, is it feasible to consider the capacity of the cutting department? What recommendations do you have?

- If you could change the lead times or lot-sizing policies used for any of the components, what changes would you make? Why?